How would you like to learn some key differences between vinyl plank flooring and vinyl sheet flooring? There are similar advantages to both lines of this product, but several key features will set them apart.

You are probably aware by now that vinyl flooring is a trendy choice for both residential and commercial spaces alike. After all, you are reading this article in search of the best solution for your flooring needs.

Table of Contents

Vinyl Plank Flooring vs. Vinyl Sheet Flooring

The polyvinyl chloride compound discovered over 100 years ago exhibits durability, outstanding wear resistance, and design versatility.

First, let us begin by taking inventory of the similarities between vinyl plank flooring (also known as Luxury Vinyl Plank) and its vinyl sheet compadre, which, as the name implies, rolls out in large sheets.

The fundamental similarities include:

- Vinyl is a durable flooring option that can last up to 25 years.

- Easy to clean and maintain.

- More comfortable underfoot than tile or other hard surfaces.

- A variety of looks, styles, textures, and colors are available.

- Slip-resistant for safer wet area application.

- Waterproof (with caveats).

- Affordable pricing options compared to other flooring types.

- DIY-friendly to install whether you choose the glue-down or floating click-lock system.

Vinyl Flooring Structure

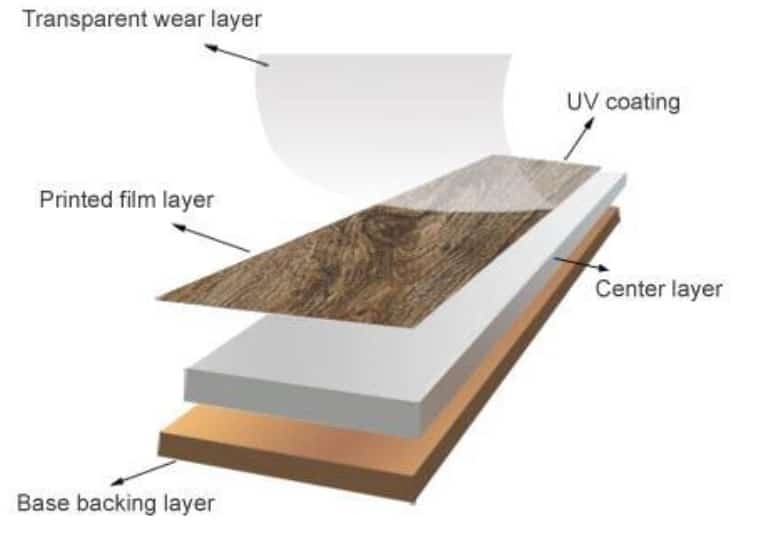

LVP (Luxury Vinyl Plank) and vinyl sheet flooring are both made from the same core material. Both flooring solutions consist of a multi-layered structure that includes the following:

- transparent wear-resistant layer

- vinyl print decoration

- rigid or flexible core

- underlayment

The quality of each of these layers may vary considerably depending on the lifetime of the product. For example, your big-box store vinyl options may range from as low as $0.50-$3.00 per square foot with a thinner wear layer and shorter lifetime warranty. Conversely, you can expect to pay as much as $12.00-$15.00 per square foot for higher-end vinyl at your nearest luxury flooring retailer.

Transparent Wear-Resistant Layer

As the uppermost layer, the polyurethane-based coating helps prevent scratches, stains, and fading. As you search for vinyl flooring, you will notice that the manufacturer measures the wear layer in mils.

Mil is an Imperial measurement meaning thousands of an inch. The wear layer of vinyl flooring typically ranges in thickness from 8 mils to 40 mils. Intuitively, the thicker the wear layer, the stronger the flooring will be. For residential spaces, professionals advise a wear layer of at least eight mils. For commercial areas, you should consider using a wear layer of at least 28 mils.

The thickness of the wear layer should coincide with the level of traffic and abuse you expect the flooring to have regularly, in addition to the total product life you hope to have from your investment.

Vinyl Print Decoration

Also known as the design layer, the print decoration layer is second from the top. This layer features a high-resolution printed image that can accommodate almost any design, color, or texture that you desire.

Manufacturers employ various printing techniques to include rotogravure printing, digital printing, and even 3-D printing.

Vinyl flooring is practically unlimited in the design finishes that it offers. It can even unnoticeably mimic wood, stone, and other luxury finishes.

Rigid or Flexible Core

I will do my best to make you aware of several distinctions between rigid and flexible core vinyl flooring. Vinyl sheet, by nature, is flexible; in part due to its production. Therefore, we may also refer to sheet vinyl as traditional vinyl flooring.

Next in line is vinyl plank flooring that initially maintained a flexible core. However, manufacturers later began to offer rigid vinyl plank, which has evolved into three main types.

Firstly, standard rigid core vinyl plank took on a higher density core but did not have additional advantages.

With time, manufacturers have needed to respond to telegraphing issues inherent with flexible vinyl (such as sheet vinyl) and flexible plank flooring.

Telegraphing occurs when “the resilient flooring conforms to substrate features or textures, coatings, adhesives, debris or other structures over which it is laid.” Unfortunately, this transfer of imperfection will eventually become visible on your flooring surface.

And, so the birth of rigid core alternatives came about for both luxury vinyl plank and luxury vinyl tile. Nowadays, the composition of your preferred vinyl plank comes as 100% hardened vinyl, SPC, or WPC.

Wood Plastic Core or Wood Plastic Composite (WPC) is a rigid-core luxury vinyl plank flooring with a wood-polymer composite. The expressed advantages of this product include a bouncier, super comfortable, and more natural-feeling underfoot.

Stone Polymer Composite (SPC) is “engineered through a combination of limestone and stabilisers,” creating a significantly more durable core. This added toughness helps this rigid-core luxury vinyl plank to withstand dangers that are most common to flooring.

Underlayment

Typically, most vinyl plank options come with attached underlayment. The purpose of underlayment is to provide a sound barrier and some cushion for your underfoot experience. It can even act as a moisture barrier in some cases.

The choice in underlayment for your flooring will usually depend on the subfloor that currently exists in your space. Common underlayment materials are foam, felt, cork, particleboard, plywood, and oriented strand board (OSB).

You will not need to buy an underlayment in most cases, as most vinyl plank flooring comes standard with either a foam or cork base layer. However, if you are laying vinyl sheet flooring, then consider one of the options above.

Vinyl Plank Flooring vs. Vinyl Sheet Flooring

Visual Appeal

Vinyl plank flooring and vinyl sheet flooring both have incredible visual appeal. The main difference will be in its authenticity. Let me explain.

You will typically install sheet vinyl in large sheets. The result is a finished room with minimal floor seams, if any at all. But, if you want sheet vinyl with artificial seam lines for a more realistic, today’s limitless printing capabilities will allow that.

On the other hand, vinyl plank flooring resembles more costly natural flooring alternatives such as hardwood, tile, marble, stone, and cement. In addition, installation of vinyl plank requires that you install each individually manufactured piece using a glue-down, click-and-lock, or floating system. So, in between each plank, a beveled seam is left that you can choose to grout in some luxury options.

Cost

When comparing costs, vinyl sheet flooring will always be the cheaper alternative. Sheet vinyl is mass-produced, and you do not need it cut into precise pieces.

Keep in mind that sheet vinyl is more costly to repair because you need to hire a professional. However, if you need to repair vinyl plank flooring, you can remove and replace the damaged plank(s) without leaving traceable marks.

One helpful tip is to ensure you purchase extra plank if you decide to finish your residential or commercial space with vinyl plank flooring.

Vinyl plank is the better choice, and with a bit of research, you will find an option to fit your budget restraints. Of course, product quality will determine overall project cost, but a 25-year warranty comes with a price.

Bottom-tier vinyl plank flooring will cost between $1.00-$3.00 per square foot, whereas high-quality designer plank will range between $12.00-$15.00 per square foot.

Practicality

Whether you need to outfit your residential or commercial space with new flooring, vinyl is a great choice. But, most importantly, you will need to consider the function of your specific area.

For example, sheet vinyl may be better adapted for a large business office, schoolhouse, or healthcare building because its seamless design will better defend against heavy foot traffic and moisture.

If instead, you want to upgrade that old carpet in your home to a natural wood or stone finish at a fraction of the cost, you will prefer the limitless design options of vinyl plank flooring.

In today’s market, there is a suitable option for your every need. I will remind you to consider your flooring option as a long-term investment. Your flooring not only adds so much character to your area, but it also absorbs the blunt impact (quite literally) of your life at home or work.

DIY Install

Vinyl sheet flooring can be a frustrating endeavor. In most cases, if you have no previous experience, you should hire a professional contractor for installation.

Installing sheet vinyl requires precise measurements and cuts to prevent material loss and additional costs. The reason for this is because sheet vinyl gets cut to fit your entire floor with one sheet.

But, on the other hand, with some help from YouTube, even a layman (or woman) can learn to install vinyl plank flooring.

Whereas you need to glue down sheet vinyl, you can choose to install plank flooring via the glue down, floating, or click-and-lock method.

Take-Away

As with any project, now it is time to break out your notepad and list out the pros and cons of vinyl flooring. Specifically, look at the differences between flexible and rigid-core alternatives and select the option best suited to your specific situation.

Depending on your budget, space, function, and personal aesthetic preferences, vinyl flooring is always an excellent choice due to its durability, versatility, and wear-resistant properties.

Please feel free to share your questions or concerns in the comment section below.

Hey, thanks for listing out these points. Going for Vinyl Plank for my new place.

Dear sir or madame,

Is sheet vinyl “less noisy” when walking upon than LVP? It is assumed that LVP has a harder surface (?) than sheet and therefore it’s noisier.

True?

Thank you.